AKKERMAN GBM240

The Akkerman Guided Boring Machine (GBM) system offers accuracy in varying ground conditions for 4-24-in. OD pipe installations when the GBM is used independently . The GBM can be used in conjunction with an auger boring rig to provide an accurate line and grade guide for critical path and sewer grade cased bores. This ”Pilot Tube” system is an extremely useful alternative to our micro-tunneling steering head system when the ground condition demands it or if the job specifications call for it. The GBM jacking frame is compact and can be set in a 12’ diameter shaft and utilized to direct jack pipes such as “No-Dig” VCP in 3’ sections from 4”-24”.

American Augers 48/54-900

MECHANICAL FEATURES

- Volvo 174 HP (130 kW) Tier IV Diesel Engine

- 900,000 lbs. (408 Tonnes) of Maximum Thrust

- 5 Speed Transmission

- Maximum Output Torque: 136,551 ft-lbs. (185,089 Nm)

- Working Range: 24 to 54 inch (610 to 1,372 mm) Casing Diameter

| DIMENSIONS | |

|---|---|

| Length | 14 ft. 6 in. (4.42 m) |

| Width | 5 ft. 9 in. (1.75 m) |

| Height | 6 ft. 2 in. (1.89 m) |

| Master Track Length | 15 ft. (4.57 m) w/1 in. (25 mm) back plate |

| Master Track Width | 5 ft. 6 in. (1.67 m) |

| Centerline | 32.89 in. (835.4 mm) |

| Extension Track Length | 10 ft. (3 m) |

| Extension Track Width | 5 ft. 6 in. (1.67 m) |

MMTS Steering Head

Malcolm Micro-tunneling Systems Steering Heads available in 16” to 60”.

ONE STEP CASING INSTALLATION

Installs on-grade/on-line casings in a single pass compared to the multiple passes required with pilot tube guided boring.

EFFICIENCY and ACCURACY ON THE JOB

Completes longer on-grade bores at reduced costs and overall project durations as compared to other methods. The steering system uses no piloting system and will render nominal accuracies of .05 feet vertically and 0.1 feet horizontally. This lateral reaction design is not prone to deflection like a pilot tube because the substantial size difference provides many times the bearing area and holding power.

BUILT-IN LEVEL SYSTEM

Continuous vertical leveling read out in the jacking pit with a built-in pressure balanced hydraulic level system .

CENTERLINE MONITORING AND MAINTENANCE

Check and maintain the line throughout the bore with A Halogen Optical Alignment Hub enclosed in the steering head.

American Augers 36-600

MECHANICAL FEATURES

- DEUTZ D914LO6 116 HP (86.5 kW) Tier III Diesel Engine

- 600,000 lbs. (272 Tonnes) of Maximum Thrust

- 5 Speed Transmission

- Maximum Output Torque: 107,257 ft-lbs. (145,540 Nm)

- Working Range: 12 to 42 inch (305 to 1,067 mm) Casing Diameter

| DIMENSIONS | |

|---|---|

| Length | 12 ft. 6 in. (3.81 m) |

| Width | 5 ft. 7 in. (1.69 m) |

| Height | 5 ft. 9 in. (1.75 m) |

| Master Track Length | 13 ft. (3.96 m) w/1 in. (25 mm) back plate |

| Master Track Width | 6 ft. 3 in. (1.92 m) |

| Centerline | 29.27 in. (744 mm) |

| Extension Track Length | 10 ft. (3 m) |

| Extension Track Width | 6 ft. 3 in. (1.92 m) |

American Augers 60-1200

MECHANICAL FEATURES

- DEUTZ TCD914LO6 174 HP (130 kW) Tier III Diesel Engine

- 1,200,000 lbs. (544 Tonnes) of Maximum Thrust

- 5 Speed Transmission

- Maximum Output Torque: 108,832 ft-lbs. (147,600 Nm)

- Working Range: 24 to 60 inch (610 to 1,524 mm) Casing Diameter

| DIMENSIONS | |

|---|---|

| Length | 14 ft. 7 in. (4.43 m) |

| Width | 7 ft. 1 in. (2.16 m) |

| Height | 7 ft. 5 in. (2.27 m) |

| Master Track Length | 15 ft. (4.57 m) w/1 in. (38 mm) back plate |

| Master Track Width | 7 ft. 4 in. (2.23 m) |

| Centerline | 36.02 in. (915 mm) |

| Extension Track Length | 10 ft. (3 m) |

| Extension Track Width | 7 ft. 4 in. (2.23 m) |

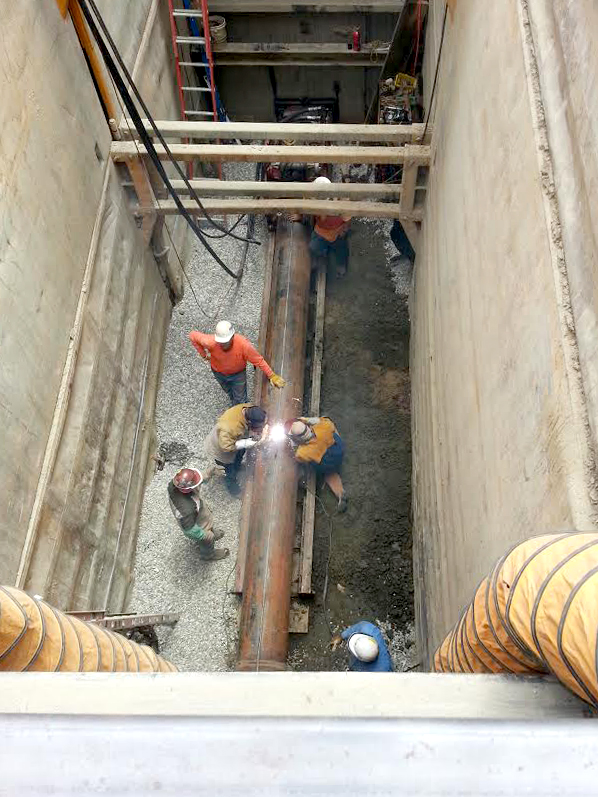

Hand Mining and Pipe Jacking

Where typical boring may not succeed in. You can rely on our proven expertise in Handmining and jacking pipe in varying hostile conditions.

Such as, split face rock, solid rock, large diameter cobbles or situations where large obstructions (concrete structures, rail road ties, abandoned bridge abutments and concrete pilings, etc.) are expected or possibly encountered.